news information

-

January 16, 2025

Robot Deburring Machine Training For ltaly Famous Client

-

November 22, 2024

Deburring machine maintenance guide: practical suggestions for extending the service life of equipment

-

November 8, 2024

Explore the advantages and features of automatic deburring machines

-

October 22, 2024

Understanding Sheet Metal Deburring Machines: Essential Tools for Metal Fabrication

-

October 11, 2024

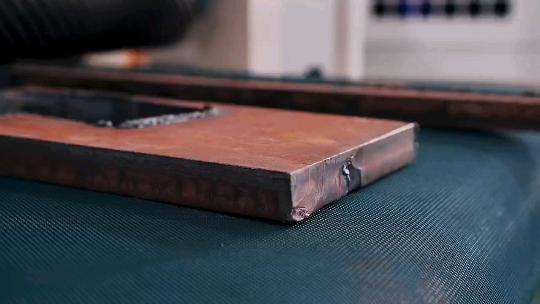

The Necessity of Sheet Metal Deburring Machines

-

September 20, 2024

Deburring Machine for Small Parts: An Essential Tool for Precision Manufacturing

-

September 10, 2024

Innovations in Deburring and Finishing Technology: What’s New in the Industry?

-

August 25, 2024

Understanding the Types of Deburring Machines: A Comprehensive Guide

-

August 15, 2024

Maintaining and Cleaning Your Deburring Machine: Essential Tips for Longevity

-

July 31, 2024

Wet vs. Dry Deburring Machines: Choosing the Right Solution for Your Needs

APPLICATIONS

Metal Tanks

Dished End&Cone

Round Tube

Water Purify

Sheet Metal Working

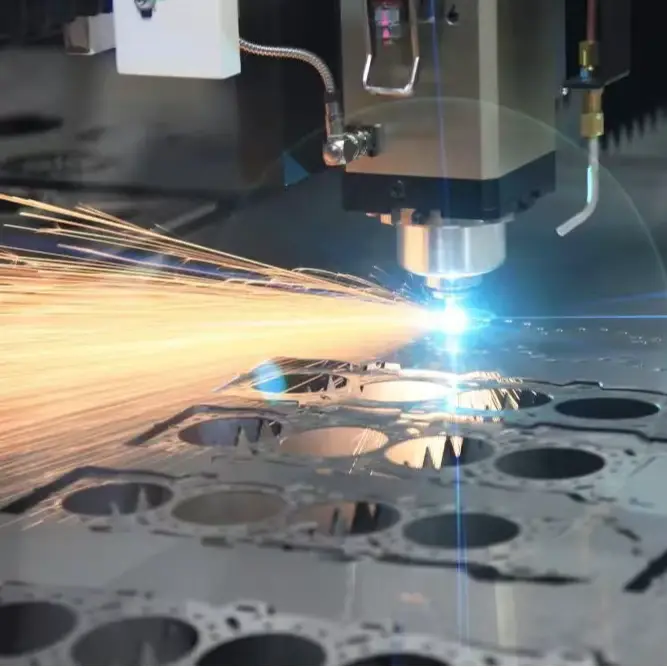

Flame cut

Laser cut

Water-jet cut

about jotun

Our company established in 2013,located in the city of Hefei in the east of China,450km away from Shanghai.We are devoted to metal surface polishing working,and exported to more than 60 countries and areas. Our vision is that our automatic polishing solutions can make customer to reduce cost,enhance productivity and output quality. while to achieve green environment.

more info-

2000

Sold machines

-

60

Sold countries

-

20

Experience Years

-

China

-

Turkey

-

USA

-

RUSSIA

-

MALAYSIA

-

USA

-

MEXICO

-

TURKEY

-

INDIA

OUR CUSTOMERS